Composite Pipe Extrusion Machine

Composite pipes production line manufacturer Sai machine tools

The PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR pipe is composed of one metallic layer, two layers of the same polymeric adhesive and two layers of same polyethylene. The inner and outer PE layers-are bonded to metallic layer (aluminium tube) by polymeric adhesive during extrusion process.

This composite pipes has some good characteristics, such as no deformation under high temperature and pressure in long time; excellent oxygen resistance, high mechanical properties, sanitary, corrosion resistance, low thermal conductivity, long life span; etc. It’s suitable for buiding systems in hot and cold water, floor heating system and air conditioning system.

Are you looking for reliable PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR composite pipe extrusion system sources?

No further than Sai Machine Tools Pvt Ltd (SMT)

Our pipe plants, which are made of the best possible material, facilitate processes to ensure top-notch quality products. Our PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR is more than just a production facility. It’s a testament to our commitment to innovation, sustainability and excellence. With our new PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR plant, we’re better equipped than anyone else to meet the needs of our customers.

Tap Here To Download Free Brochure

Composite machine highlights

Raw Material: PE granules, Aluminium Strip

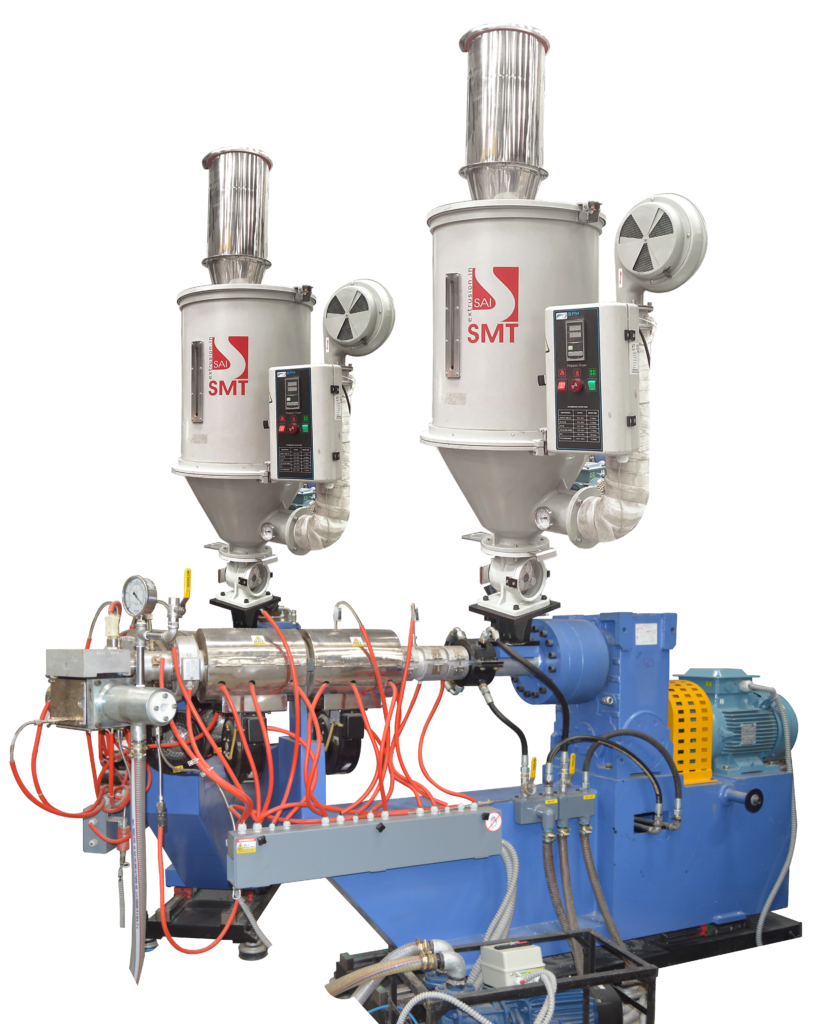

Extruder: SMT-45X45X45X45

Products: PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR Pipe

Output capacity: 120-150 kg/hr. (max.)

Layout: For pipe range ½” to 2”

Sai Machine Tools PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR Pipe Production Line: A Feature-Packed Powerhouse for Efficiency and Quality

Overlap welding plastic aluminum composite pipe production machine, with advanced technology and plenty practical experience.

Ultrasonic welding technology for aluminum pipe welding, with firm and even welding seam.

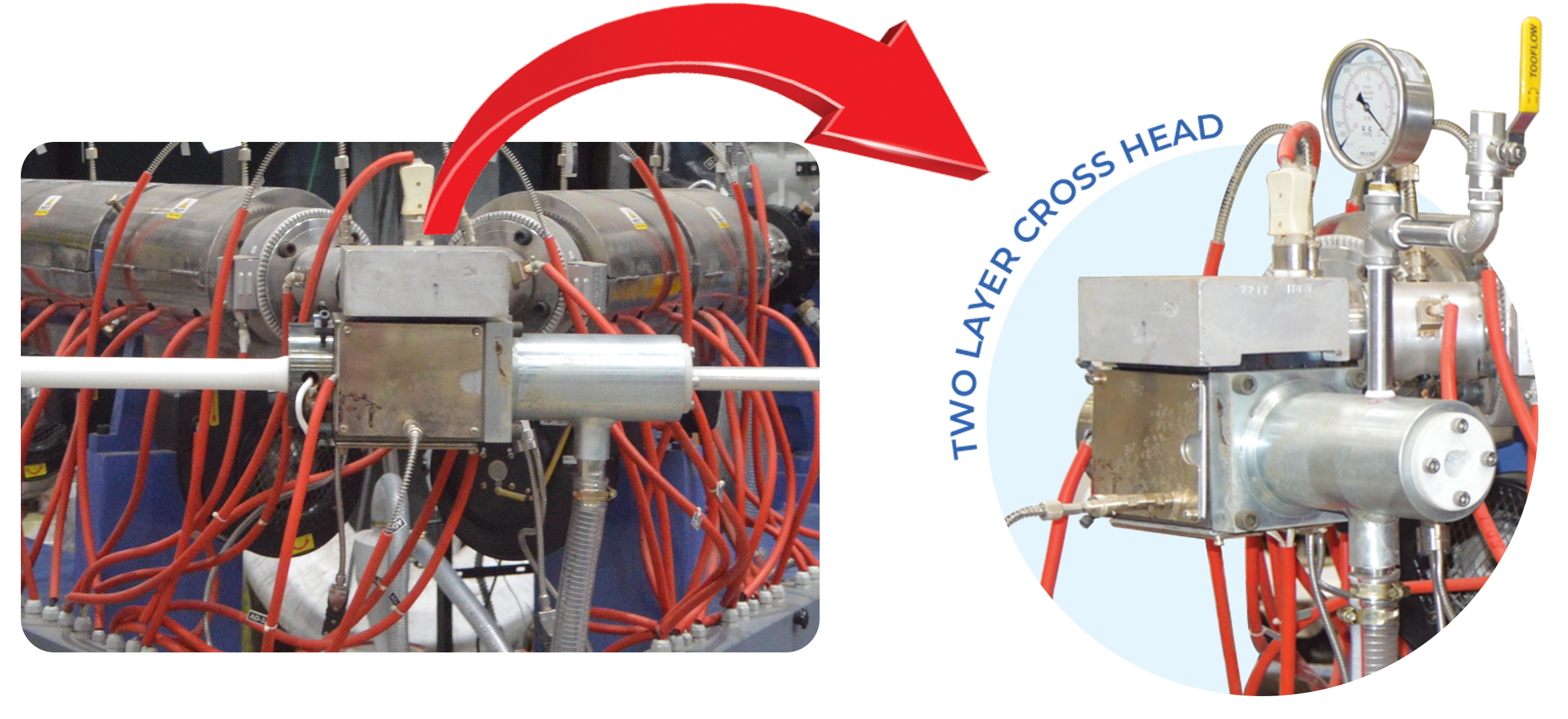

Al pipe forming mold and co-extrusion die head mold are further optimized based on our years experience and manufactured by precise CNC machine, greatly increasing the pipe forming accuracy and production speed.

mitsubishi programmable PLC control with big color touch screen. Having multi-point close-loop control and synchronous system, which ensure the easy and reliable operation of the line.

Production line series: PEX-AL-PEX, PERT-AL-PERT, PPR-AL-PPR, PE-AL-PE etc.

Unlocking Precision: A Deep Dive into the Specifications of Sai Machine Tools' PPR/PEX/PERT/PE-AL-PE/PERT/PEX/PPR Pipe Machine