PVC Pipe Extrusion Machine

Sai Machine Tools: Affordable PVC Pipe Extruder Machine Price

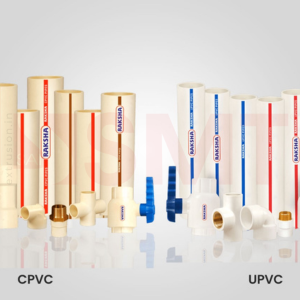

As a leading manufacturer of PVC pipe making machines SAI MACHINE TOOLS, catering to the needs of UPVC and CPVC pipe manufacturers. Our highly advanced machines boast an impressive output capacity ranging from 75kg/hr. to 350kg/hr. To ensure exceptional performance, we offer a wide selection of high-capacity PVC/CPVC extruders, featuring screw diameters ranging from 51/105mm to 65/132mm. The conical extruder incorporates highly advanced and innovative screw construction, resulting in the production of top-quality pipes with minimal rejection rates. Furthermore, our pipe extrusion machines are built with a robust design and construction to withstand rigorous operation. The integrated PLC control system in our PVC/CPVC pipe-making machines enhances their performance while also offering user-friendly operation.

Unleash Efficiency: Conical Twin-Screw CPVC/UPVC Pipe Plants - Your PVC Pipe Making Machine Solution

Looking for a reliable manufacturer for your next PVC pipe extrusion system?

No further than Sai Machine Tools Pvt Ltd (SMT)!

Our pipe plants which are made of the best possible material facilitate processes to ensure top-notch quality products. Our cPVC-uPVC pipe (Twin screw) – conical plant is more than just a production facility. It’s a testament to our commitment to innovation, sustainability and excellence. With our new CPVC UPVC pipe twin line plant, we’re better equipped than anyone else to meet the needs of our customers.

PVC machine special feature

Low price with high performance: We strive to deliver cost-effective solutions without compromising on quality or performance.

Versatile extruder: Our unique extruder design allows for the processing of both CPVC and UPVC materials, providing versatility and convenience.

Triple chrome-plated die: The die component of our machines is coated with triple chrome plating, ensuring durability and longevity.

At Sai Machine Tools, we are committed to delivering state-of-the-art plastic processing machinery, meeting the diverse needs of our valued customers. With our unwavering focus on quality, performance, and customer satisfaction, we continue to be a trusted name in the industry.

Conical twin screw PVC machine specification

| MODEL | SCREW TYPE | Down Stream | Screw Dia (MM) | Main Motor (KW) | Max. Output (Kg/Hr.) | Pipe Range (Inch) |

|---|---|---|---|---|---|---|

| SMT – 65/132(ß)-200 | Conical TWIN SCREW | Single | 65/132 | 55 | 250-350 | 2" - 8 |

| SMT – 65/132(ß)-TDS-50 | Conical TWIN SCREW | Dual-CD-200 | 65/132 | 55 | 250-350 | 1/2” – 2” |

| SMT – 80/156-TDS-110 | Conical TWIN SCREW | Dual-CD-510 | 80/156 | 75 | 400-500 | 1/2” – 4” |

Subsystems:

Why choose Sai Machine Tools cPVC/uPVC Pipe extrusion machine

Why buy PVC pipe extrusion machines from Sai Machine Tools?

What kinds of PVC pipes can you manufacture with your machines?

Why are your PVC extruders able to work efficiently than your competitors?

Are your PVC pipe making machines durable?

What production capacities are your PVC extruders able to do?

Will your machines work for UPVC and CPVC?

What are the control systems for your PVC extruders?

Do you provide after sales service?

Why is your conical twin-screw design better for PVC extrusion?

What pipe dimensions can your machines make?

How energy efficient are your PVC extruders?

What makes your dies more durable than competitors?

Can your machines process recycled PVC?

What safety features do your machines have?

Why should I buy PVC machines from Sai Machine Tools?

With over three decades of expertise, guided by Mr. Ashok Jaiswal, SMT leads the industry in innovation and growth, with a global reach exporting 30% of our products.

SMT’s advanced production facilities, coupled with 3000+ global installations, guarantee top-tier products, all crafted under one roof for quality control.

Led by Technical Director, Mr. Vishal Jaiswal, our proficient team ensures each product reflects quality, reliability, and cutting-edge technology.

Our commitment to quality starts with the materials we use. We source only the finest materials, guaranteeing durable and reliable products.

Our skilled technicians handle the installation process, ensuring seamless integration of our machines into your operations.

We don’t just deliver machines; we empower you with the knowledge to operate them effectively. We offer thorough training until you’re confident and capable.

Every machine undergoes rigorous testing to ensure it meets the highest standards of performance and reliability before it reaches your facility.

Your success is our priority. Our dedicated customer support team is available to assist you with any questions, concerns, or issues you may have.

We believe in building lasting relationships. Our machine servicing ensures that your equipment continues to perform optimally throughout its lifecycle.